BYD K9 Project: combining EV battery cooling system with electric bus air conditioning

Project background: We have already had in-depth OEM cooperation with BYD on electric bus air conditioning. BYD is very satisfied with the cooling capacity, technical strength, service and delivery cycle of our bus air conditioners. Because they trusted our technical capabilities, they entrusted us with this difficult development project again. If the research is successful, it will further enhance the competitiveness of BYD electric buses in the market. The red BYD k9 electric bus in the picture uses our company AC combine chiller. This system perfectly combines EV battery cooling system with electric bus air conditioning. This innovation not only improves cooling efficiency, but also reduces energy consumption and equipment space occupation. It has made outstanding contributions to improving BYD k9 electric bus performance and reducing costs.

AC Combine Chiller Advantages

EV battery cooling system requires lower cooling capacity, so the performance of the compressor used in the traditional system is weaker than that of the electric bus air conditioning compressor. This can reduce battery cooling equipment costs. After a long period of research and experimentation, TKT busthermo team of engineers successfully integrated two separate systems. In AC combine chiller, they can share many components, such as more advanced electric compressors. This breakthrough technology not only improves the cooling effect, but also effectively reduces the energy consumption and cost of the cooling system.

In terms of the battery cooling system effect of electric vehicles, the new equipment achieves precise control of battery temperature at 0.5°C. This ensures the stable operation of the BYD k9 electric bus power battery and further improves the safety and reliability of the bus. In terms of the air conditioning effect of electric bus, the new equipment is as stable and efficient in cooling as ever, ensuring a comfortable travel experience for passengers. Secondly, due to the perfect combination of the two systems, additional equipment footprint is reduced. With the extra space, you can choose to install more batteries to increase the driving range. The reduced space also reduces the weight of the vehicle and reduces energy consumption, further improving the market competitiveness of BYD k9 electric bus.

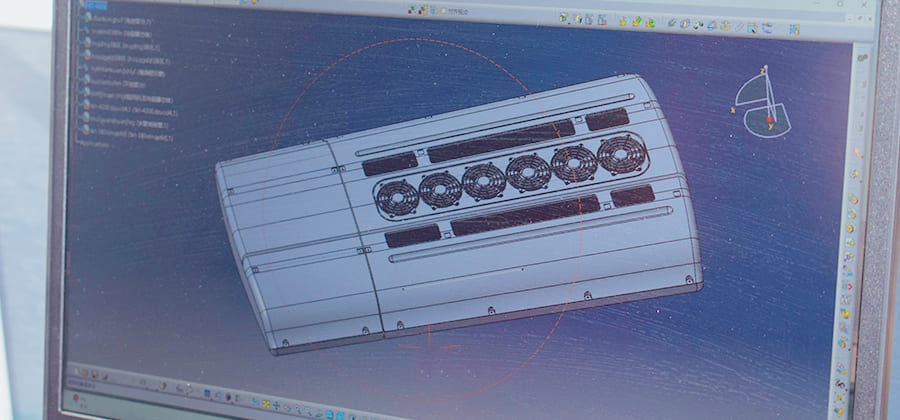

AC Combine Chiller Debugging

Get more information on EV battery cooling system, AC combine chiller, etc.

WhatsApp: +86 13015505615

Facebook: https://www.facebook.com/TKTHVAC/

linkedin: https://www.linkedin.com/company/tkt-hvac

YouTube: https://www.youtube.com/@TKTHVAC

Original article for more details - https://www.busthermo.com/ev-battery-cooling-system-news/

评论

发表评论