Electric Bus Charging Station Types

Currently, there are two mainstream methods for charging electric buses. They are Pantograph Charging and Plug-in charging.

Pantograph Charging

Pantograph Charging is a charging method specially designed for electric buses. This charging equipment automatically connects to the charging interface on the top of the electric bus through a professional robotic arm, and then transmits electric energy.

Specific steps: When an electric bus enters the charging area, the charging device will automatically identify and locate the charging interface on the top of the bus. The robotic arm will then move precisely to ensure perfect docking with the charging port. Once the docking is successful, Pantograph Charging can start charging the battery of the electric bus.

|

| electric bus charging solution |

The main advantages of this electric bus charging station solution are automation, efficiency and safety.

1. Automation: This solution does not require manual operation, the system will automatically recognize the signal, start and end.

2. Efficiency: It can quickly and accurately connect to the charging interface of the electric bus, reducing preparation time and improving charging efficiency.

3. Safety: Since the charging process is automated and the equipment is designed with safety factors in mind, such as preventing electric shock and overheating, this method is highly safe for both people and equipment.

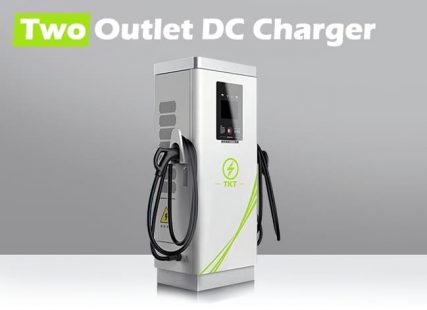

Plug-in charging

Plug-in charging, which is the ordinary DC charging method. It first obtains AC power from the power grid, and then converts the AC power into DC power through an internal inverter. This DC power is then delivered to the battery of the electric bus for rapid charging.

Specific steps: The staff accurately inserts the connector of the DC charger into the electric bus. Then use the charging card to set the time or power of the charger. Finally turn on charging.

|

| TKT electric bus charging station |

Compared with Pantograph Charging, its advantages are that the cost is relatively low, the construction of charging stations is less difficult, and the scope of application is wider. Almost all electric buses can be used. There is no need to distinguish between specific bus makes and models. Therefore this charging method is the most common fast charging method for electric buses.

TKT Electric Bus Charging Station Project for BYD — Olectra

This project is our cooperation with BYD Olectra, a famous Indian electric bus manufacturer. The number of charging stations in the first batch exceeds hundreds. In this project we are honored to work with Dinesh Navgire from Olectra. He is an electrical engineer with extensive experience and professional skills. He focuses on the operation and maintenance of electric bus charging infrastructure. He has efficient solutions for the maintenance and management of EV charging infrastructure, which can ensure the stable operation and efficient use of charging facilities. Our collaboration focuses on improving the performance and experience of EV charging stations. He worked closely with our team to ensure the smooth progress of the project, demonstrating excellent professionalism and teamwork.

|

| TKT electric bus charger project |

For more details, visit the TKT website.

WhatsApp: +86 13015505615.

评论

发表评论