Overview of Articles

The choice of an EV DC charger is a complicated one. Especially how much charging power to choose. Choosing a large one adds unnecessary costs, choosing a small one is weak in terms of profitability when operating. In addition, is there any special feature that you need to pay attention to when choosing a DC charger? Let me give you a detailed explanation.

|

| How to Choose EV DC Charger |

The first thing you need to know is that the cost of purchasing a EV DC charger is relatively large. Next, you need to know information about the local electric vehicle battery information, the location of the layout, the charger’s features, price, support and after-sales and other factors.

1. You need to know about local electric vehicles.

First of all, the information you need to know is the electric vehicle model. Through the EV model, you can clearly understand the EV battery energy, charging interface, and the maximum power that the EV battery can accept.

EV battery energy: This is a necessary factor to roughly calculate the charging time.

There are four common standards for charging interfaces: CCS1, CCS2, CHAdeMO, GBT. TKT EV DC charger supports all interfaces, and you can choose any two combinations. With this option, customer coverage is wider. In the case of Tesla cars, the NACS of early cars can use charging adapters to achieve fast charging. If it is the latest car, there are already connectors that support CCS1 or CCS2.

|

EV DC Charger Interfaces |

Maximum power: Fast charging of EV is determined by two aspects. On the one hand, it is the power of the EV DC charger. On the other hand is the maximum power that the battery management system of an EV can accept. If the battery management system of an EV has limitations, then there is no point in equipping it with a super-powerful charger.

2. You need to know where your layout is.

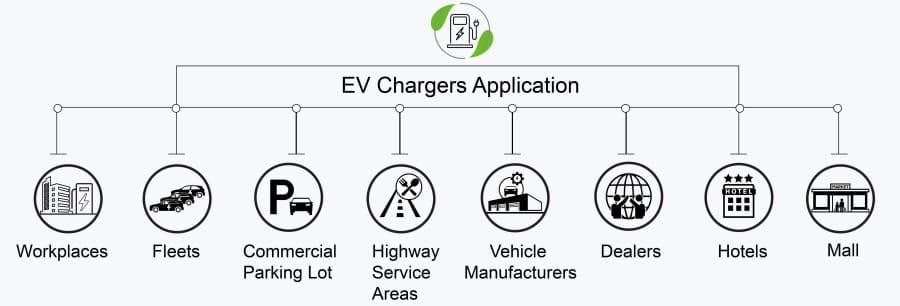

Common types include: shopping malls, logistics fleets, bus fleets, highway service areas, hotels, etc. Based on the actual scene and type of electric vehicle, the usual parking time is comprehensively judged to roughly calculate the charging power.

|

EV Chargers Application |

For example, in a shopping mall, people usually spend 2–6 hours shopping in the mall. Their vehicles are usually private car types, and the battery energy is usually 15–60kWh. Taking 60kwh as an example (regardless of the power conversion rate and electric vehicle charging restrictions), the minimum parking time is 2 hours. In this case, a 30kW EV DC charger can be selected. But I prefer to choose 60kW. This is because current DC charging stations usually have two outlet, which maximizes utilization. Considering that two cars will be charged at the same time, I recommend choosing a 60kW charging station.

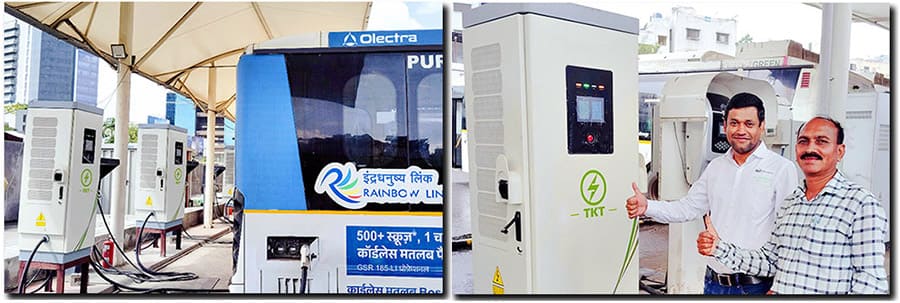

If it is an electric bus fleet. The battery energy of this type of vehicle is relatively large, usually above 150kWh. It is recommended to choose the electric bus charging station with the highest power. A 30kW charger takes 5 hours to fully charge. The 360kW charger can charge the battery in just 25 minutes. The faster an electric bus can be filled, the more trips can be scheduled. This will help maximize profits. The premise is that the electric bus can accept 360kW charging power.

|

Electric Bus Charging Station Project For Olectra |

3. Essential EV DC charger functions

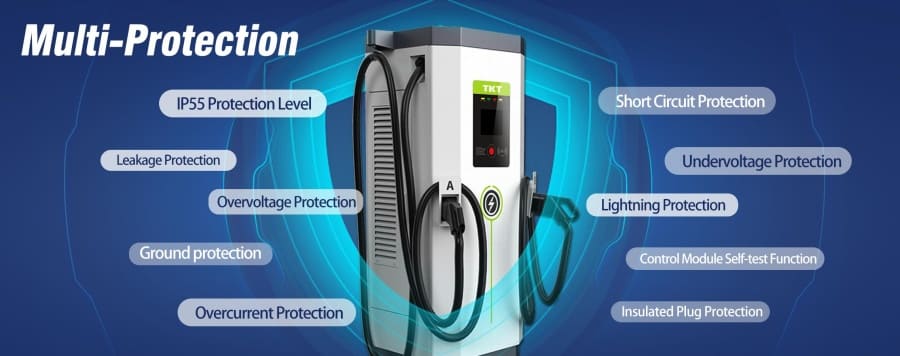

3.1 Security protection

DC chargers draw high currents and voltages, which can be fatal in the event of an accident. Therefore, when choosing a EV charger, be sure to pay attention to whether it has multiple safety protection functions. TKT EV DC charger attaches great importance to safety. From the inside to the outside, from hardware to software, it is designed with multiple protection functions. Such as overvoltage protection, undervoltage protection, overcurrent protection, short circuit protection, BMS independent safety protection, plug insulation detection, self-test function control module, etc.

|

| Security protection |

3.2 Dynamic load balancing

Advanced DC chargers intelligently allocate charging power through dynamic load balancing functions. It will adjust in real time according to the conditions of the vehicles being charged at the same time to maximize the charging power. I illustrate its meaning through images.

|

Dynamic load balancing |

Mode 1: When only one car is charging, the DC charger can concentrate the charging power.

Mode 2: When two identical cars are charging at the same time and both cars have low power, the system will allocate 50% of the charging power to each.

Mode 3: When two cars are charging at the same time, but the remaining power of the two cars is different. The system dynamically allocates power based on remaining power, enabling higher profits for charging stations.

Other modes: When the maximum charging power of car A only supports 30kW, the charging power of car B can reach 100%-30kW. This is more efficient than early average allocation.

TKT DC charger has more advantages and features. To learn more please click.

4. Price, technical support, after-sales

Smart you should know that no product can be the best in every detail. EV DC charger that are too cheap will inevitably have at least one shortcoming in quality, performance, and after-sales service. Don’t blindly focus only on price.

A DC charger is a relatively expensive device. Installation and power configuration are also complex. We recommend that you choose an experienced ev charger manufacturers who can provide strong support. TKT has over 10 years of manufacturing and support experience. We have a professional team of engineers. They will provide video technical support to ensure everything goes smoothly during your installation and use. We have this confidence. Do not worry.

|

TKT EV Charger Manufacturers |

Contact Our Experts Now.

WhatsApp: +86 13015505615

Facebook: https://www.facebook.com/TKTHVAC/

linkedin: https://www.linkedin.com/company/tkt-hvac

YouTube: https://www.youtube.com/@TKTHVAC

评论

发表评论