Similarities: Bus Coach Air Conditioning System of Electric and Conventional

I. Working Principle (How does air conditioning work in a bus?)

Heat exchange underlying principle: Both types of bus coach air conditioning systems follow the heat exchange principle for cooling. In this process, the evaporator is responsible for absorbing heat inside the bus. It then causes it to be transferred to the refrigerant. While the condenser is responsible for releasing the heat from the refrigerant outside the bus.

In this process, the refrigerant is continuously compressed, condensed, throttled and evaporated through the action of the compressor. When the air conditioner is running, this process will cycle back and forth. The air conditioner is then able to continuously transfer heat from inside the bus to outside the bus. This achieves lower temperatures and increased comfort inside the bus. Both electric and engine-driven compressors play a key role in the air conditioning system.

II. Control System

III. Maintenance and Repair

If you are interested, welcome to read the original text.

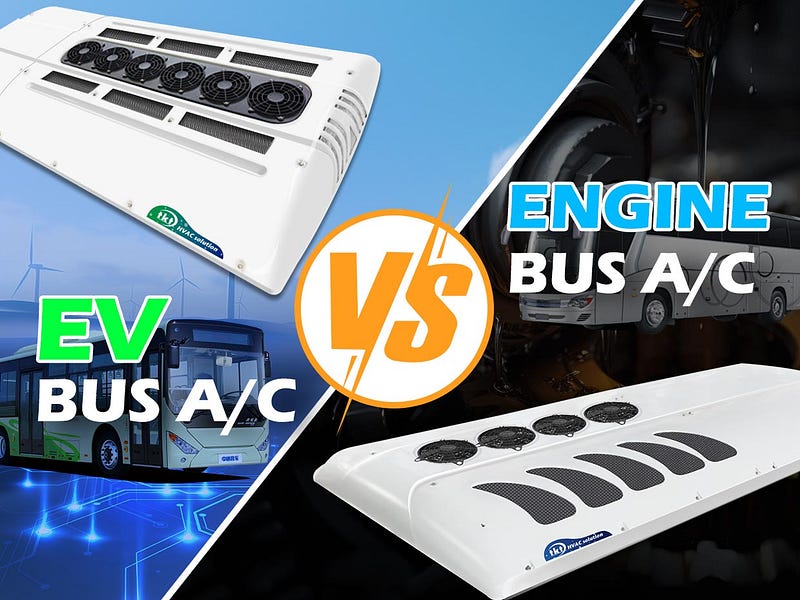

Differences: Bus Coach Air Conditioning System of Electric and Conventional

I. Power Source (Driving Method)

Electric bus air conditioner system: Its power comes directly from the high-voltage power supply of the electric bus and works through an electric compressor. This design makes full use of the electric power advantage of electric buses. There is no need to rely on the engine to provide power, achieving efficient use of energy.

Conventional bus air conditioning system: Power is usually supplied by a compressor driven by the engine belt. This design is very common in fuel buses. However, it is not applicable to electric buses, which do not have a conventional internal combustion engine.

II. Energy Efficiency and Energy Saving

III. Environmental Friendliness

If you are interested, welcome to read the original text.

Bus Coach Air Conditioning System Summary:

Electric bus coach air conditioning system have many advantages. However, not all buses are suitable for electric bus air conditioning. It is only suitable for fully electric buses because it is powered by a high voltage power source. From the point of view of cooling capacity, there is no essential difference between the two. So there is no need to be anxious. Just choose a reasonable cooling capacity and type of air conditioner according to your bus. The energy efficiency ratio of conventional buses is improving with the upgrading of various parts such as compressors.

Established in 1998, TKT HVAC is a specialised bus coach air conditioner manufacturer from China. We have extensive experience in OEM design and manufacturing of both conventional and electric bus air conditioners. We are the bus air conditioning supplier for BYD and TATA Motors, the world’s top 500 vehicle manufacturers. If interested, please feel free to click to browse their co-operation cases.

Diesel Bus Air Conditioner Solutions

【For 13–14m Diesel Bus】 【For 12–13m Diesel Bus】 【For 11–12m Diesel Bus】 【For 9–10m Diesel Bus】 【For 7–8m Diesel Bus】【For 6–7m Diesel Bus】

Electric Bus Air Conditioner Solutions

【For 10–12m Electric Bus】【For 9–10m Electric Bus】 【For 6–7m Electric Bus】

If you are interested, welcome to read the original text.

Official website: https://www.busthermo.com/

评论

发表评论