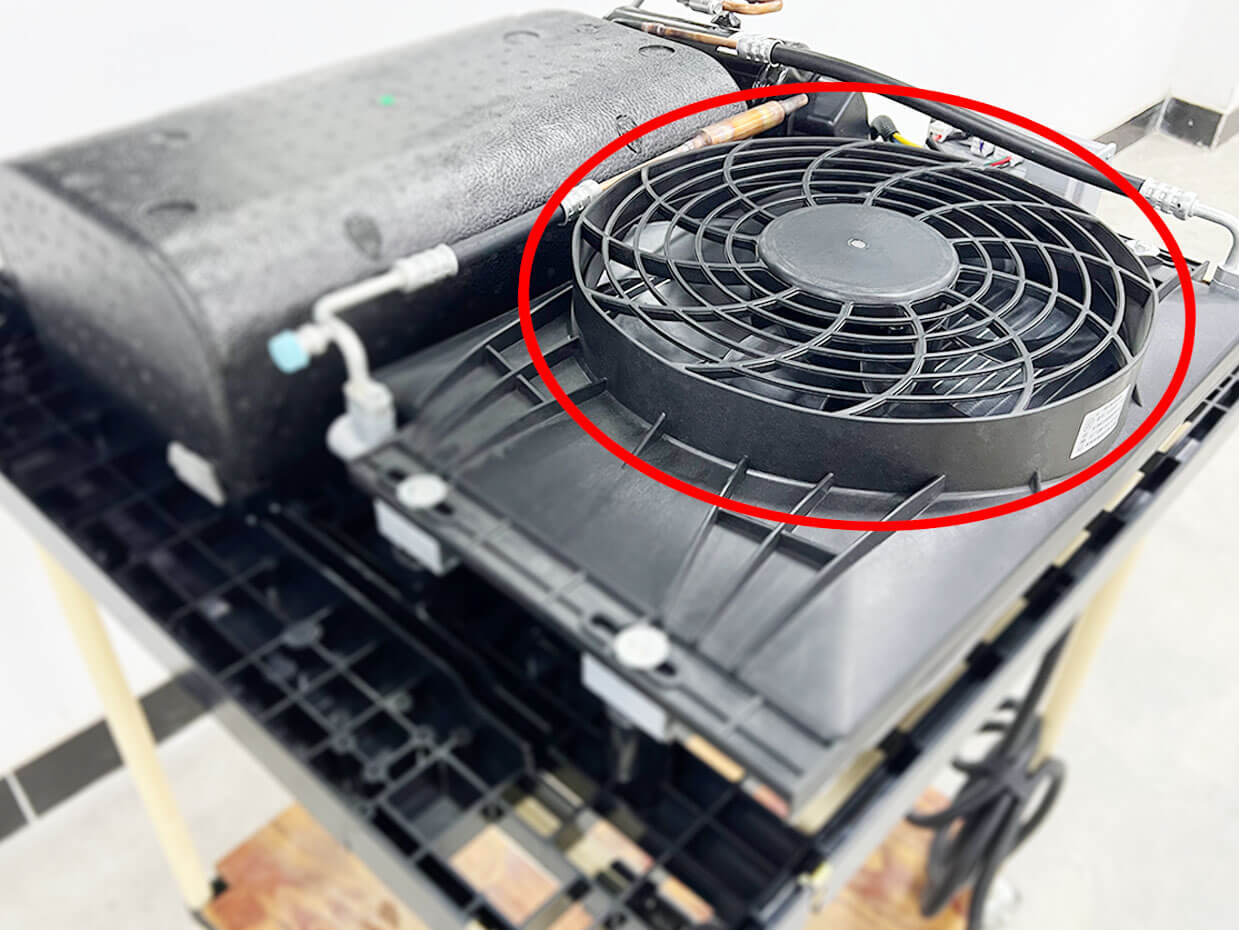

A truck's air conditioner system consists of a number of key components that work together to achieve cooling and heating. The core components are: compressor, condenser, condensing fan, evaporator and evaporating fan. Together, these truck air conditioner parts ensure the proper functioning of the air conditioning system.

Truck Air Conditioner Parts - Fans

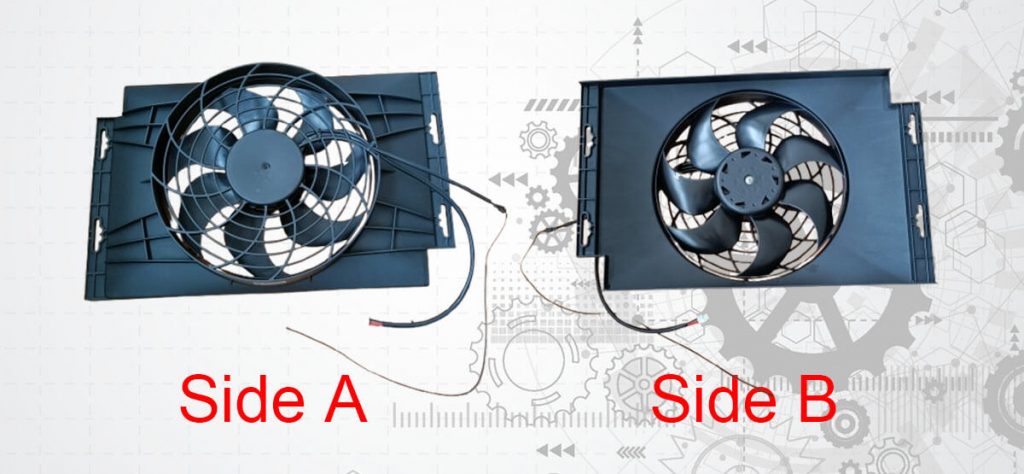

Fans for truck air conditioners are divided into two main types: brushed fans and brushless fans, both of which are distinctive in their structure, durability, and performance presentation.

Brushless fans, in particular, adopt a more cutting-edge design concept. Its operating principle is based on the interaction between the magnetic field generated by the stator coils and the rotor permanent magnets, eliminating the need to rely on physical brushes for commutation. The significant advantages of brushless fans are reflected in their excellent energy efficiency ratio, low noise output, high RPM performance, and long service life. By eliminating brushes, brushless fans avoid problems such as brush wear and brush sparking, ensuring smoother and more reliable operation.

In addition, brushless fans are often used in high-end truck air-conditioning systems because they offer a wider range of speed adjustments and more precise control of airspeeds, allowing them to flexibly adapt to a wide range of usage requirements.

For other more detailed content, please feel free to browse the original article. https://www.busthermo.com/truck-ac-parts-fan-news/

评论

发表评论